How does a perfect China Ihomagic product come about? As a factory,

Jiangshan Wanda Industrial & Trading co.,ltd has been working in the home storage industry for 20 years, Wanda knows every step of the way.

Now

China Ihomagic home storage manufacturer will show you step by step how we make an idea into a real product that reaches the consumer.

1. Preliminary ideas

The idea may come from our designers, the idea may also come from our customers, customers often ask our designers to help them design products according to their ideas, customers sometimes have some ideas are idealistic and difficult to realize, Wanda will give our customers suggestions for improvement based on our 20 years of production experience, and discuss with customers to come up with a perfect solution.

2. Market research

Once we have an idea, we have to do market research and do a feasibility study. Study results show feasible, we'll progress to the next step.

3. Sketch the design

Once the feasibility study passes, we turn the idea into a visible sketch and then discuss improvements with the client or within the designers.

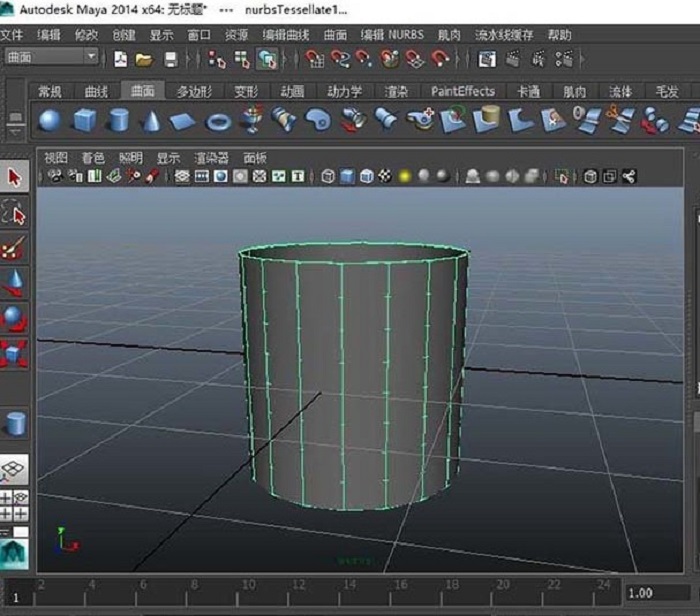

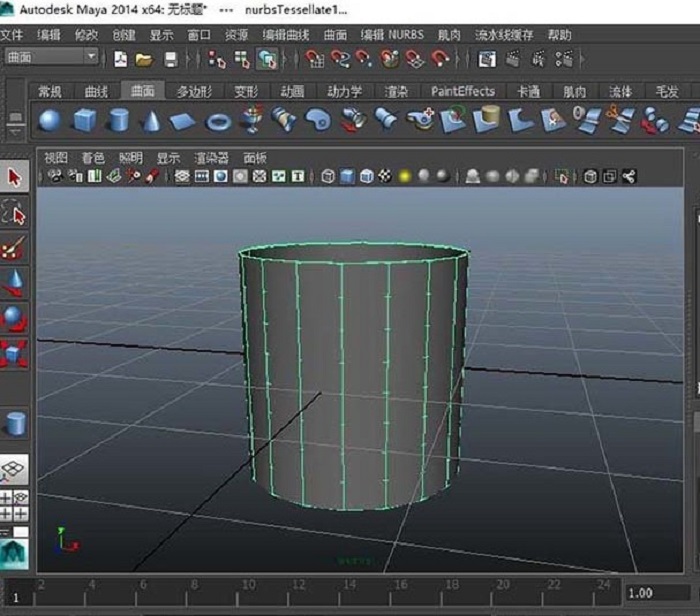

4. Make 3-D product drawing

After the discussion, 3D drawings of the product will be created using computer software, and the drawings will be further adjusted and improved until the functionality and shape of the product meet the customer's needs.

5. Make a prototype for testing

Making a prototype is a very important step, with the prototype, we can feel exactly what the final product will look like and what the function will be. If the prototype sample does not match the customer's expectations, we can continue to the previous action, modify the drawings, until the customer is satisfied.

6. Final sample

We will send the sample to customer for confirmation after the final sample has been checked by our quality department. At last, customer sign back the final sample.

.jpg)

7. pre-production meeting

Before mass production, our technical team in the production department will organize a pre-production meeting to discuss and inform the production department of the problems should be avoided during the production process, based on the problems encountered during the previous mold testing and the problems that customers may feedback after receiving samples.

After all the above seven points are done, the molds will be officially put into production, and customers will soon receive the perfect mass production goods.

I, Home, Magic——your magician at home.

.jpg)